Resilience has a broader implication for supply chains affected by wars, natural catastrophes, social and economic upheavals. Resilience is the ability to come back to a previous state after a disruption and be even stronger than before (as distinct from robustness which only means resistance to a disruption).

Resilience is key for supply chains

Supply chains suffer increasingly from a host of catastrophic events worldwide. Such events have multiple and unforeseen impacts on their ability to deliver the products and services that consumers require. In 2020, an unprecedented pandemic has stopped production of mundane or essential products. An important aspect of a supply chain is its ability to overcome such impacts: this ability is named resilience. In sociology, resilience characterises an organization that is able to rebuild itself after having been substantially affected by an exogenous attack. In a supply chain, resilience is understood as enabling vulnerabilities to be detected on an ongoing basis and so for contingency planning to be consistently updated. Resilience also means that there is a good visibility along the whole chain in particular to detect and evaluate the risk from events early.

Our research focuses on the managerial practices which can help the supply chain manager, as central decision maker, to organize the resources, routines, processes and labour in such a way that unforeseen and disrupting events can be overcome with minimal cost and delay.

Understanding how resilience can be built

We position this research in the dynamic capabilities of the Resource Based View of the firm. In this vision, firms and supply chains are built from physical and immaterial resources put in motion by personnel through routines, processes, software. The manager’s role is to dynamically adapt such resources and routines to meet the challenges from competitors, customers but also from catastrophic events.

Our results show which of the various managerial tools and practices available to a supply chain manager effectively help a supply chain to be resilient. To understand in practice which are the best ones, we surveyed 171 supply chain managers in France. These deploy in their organisations dozens of different tools, practices and routines, not to mention specific human skills and software.

Which type of managerial practices lead to which capabilities?

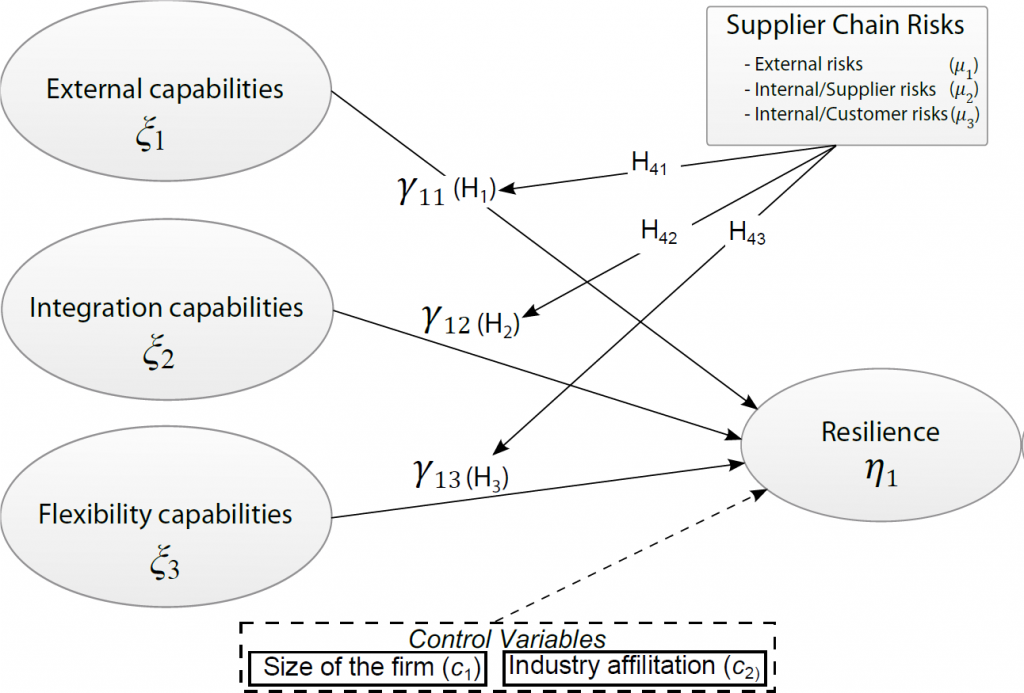

It is necessary to first categorise risks affecting a supply chain. These are usually divided between internal (inside the organisation and under the direct purview of the manager) or external (from partners in the supply chain). This led to grouping practices which bring certain specific capabilities (lower order capabilities) into three homogeneous groups. Each group, named “higher order capabilities”, bring a much more powerful set of capabilities: external capabilities, flexibility capabilities, integration capabilities. Integration capabilities provide cost reduction, risk response coordination, and improved communication. External capabilities imply efficient customer response, controlling inventories throughout the chain and increasing visibility on flows throughout the chain. Flexibility results from developing alternative suppliers as well as versatile and flexible facilities.

Analysis of the results

We find that external capabilities as defined do not provide the necessary resilience to the supply chain: the ability to ensure that the chain is able to satisfy the customer wherever and however she wants through the monitoring of the inventory of products throughout the chain does not provide sufficient protection in case of disruptive events (like a pandemic).

On the other hand, the integration and flexibility capabilities do have an important impact on the overall resilience of the supply chain. We further analysed if these capabilities were more important in the case of external, internal or supplier risks. Surprisingly the external risks have a limiting effect on the strength of external capabilities on resilience. On the other hand, we find that the higher the supplier risk, the higher the integration capabilities are and hence also, the higher the resilience of the whole supply chain.

Managerial implications

We confirm through this study that resilience is not easily enhanced and requires very specific tools, practices, and trained personnel to be deployed throughout the supply chain under the supervision of the supply chain manager. From the dozens of managerial policies and tools that managers do use on a daily basis, only a few enhance resilience. Integration is required which means that managers must not only use information technology tools and routines to integrate their internal organization (through their ERP) but also use other supply chain management software to integrate their suppliers, customers, distributors, and logistics service providers. These efforts enhance collaboration by sharing forecasts and sales data and allowing continuous inventory adjustments. In conjunction with logistics service providers, using track and trace technologies for goods provides advanced tip-offs about events and glitches that affect service levels and quality. It is a notable result that the supply chains affected by high supplier risk concomitantly deploy these integration practices and resources.

Flexibility will also enhance resilience as the ability to meet new demands in terms of product type or quantities. The second is the ability to reconfigure the supply chain (upstream and downstream) by flexibly deciding whether to make or buy, to change locations, or to implement site specialization, while keeping tabs on a pool of suppliers.

This research is based upon the results from the “Baromètre de la Supply Chain” project led by CapGemini Consulting Paris, in conjunction with Ecole Centrale Paris, and with the support of Supplychainmagazine.fr.

Xavier Brusset and Christoph Teller, Supply Chain

Capabilities, Risks, and Resilience, Intern. Journal of Production Economics,

http://dx.doi.org/10.1016/j.ijpe.2016.09.008